One of the significant benefits of using a Plastic Film Shredding Densifying Line is the versatility of the compressed material. Dense materials can be fed into a repelletizer, used as a raw material for manufacturing new products, recycled, or disposed of. This means that businesses have greater flexibility in how they manage their waste or recyclables.

Another benefit is when transporting recyclables or waste, companies face a significant challenge – the need for economy and efficiency. Loose materials take up a lot of space, which not only increases transportation costs but also damages the bottom line. However, we have come up with an innovative solution to this problem. The Plastic Film Shredding Densifying Recycling Line can compress lighter materials into denser materials that are easier to store or transport.

In conclusion, Plastic Film Shredding Densifying Line offer an innovative and cost-effective solution for businesses that need to transport recyclables or waste like Mixed plastic or PP bags. By compressing lighter materials into denser material, businesses can save money on transportation costs, improve efficiency, and reduce their carbon footprint. Investing in a scrap densification system is a smart decision for any business looking to improve its waste management processes and bottom line.

Using densified plastic film for chemical recycling has become the new trend in recycling PE and PP plastic films in the USA and around the world.

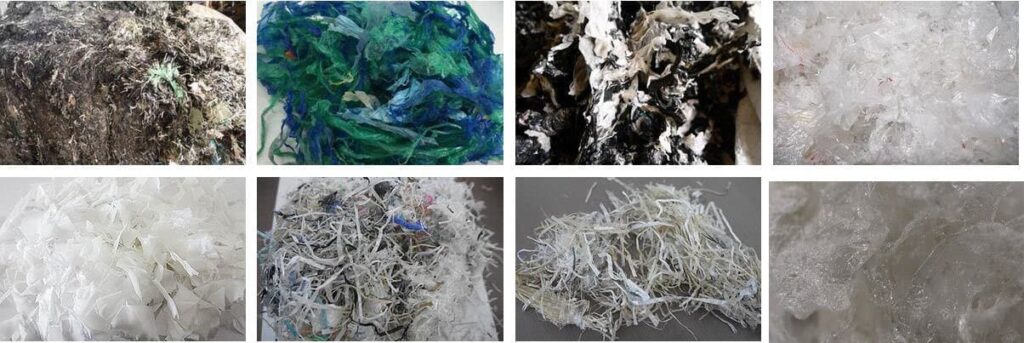

Our Plastic Film Shredding Densifying Recycling Line is your complete solution for turning dirty bales of PP/PE films into densifiedproduct ready for chemical application or processing into plastic granules via pelletizing. We offer standard capacities from 200kg/h up to 1000kg/h and can also manufacture as per your requirements.

we are committed to providing our clients with innovative and efficient solutions to their material transportation needs. Contact us today to learn more about how our Plastic Film Shredding Densifying Line can help your business.