Are you looking to start or improve your plastic bottle recycling business? Look no further than our complete PET bottle washing line. This fully automated, turnkey solution is the ideal way to process baled PET bottles into contaminant-free PET flakes.

With our PET bottle washing line, you’ll be able to sell high-quality PET flakes for top dollar to manufacturers of polyester staple fiber. You can also pelletize these flakes into granules for use in manufacturing other PET products.

But the benefits of a PET bottle washing line don’t stop there. By recycling plastic bottles, you’ll help reduce the amount of waste in landfills and oceans, conserving natural resources and reducing greenhouse gas emissions. Plus, you’ll be contributing to a circular economy, where materials are reused and repurposed rather than

discarded.

With its worldwide experience in the field of PET bottle washing and recycling, we can provide customers with proper technical solutions and state-of-the art recycling technologies, delivering a response tailored to the frequent changing needs of customers and market.

Investing in a PET bottle washing line is not only good for the environment, but it’s also a smart business decision. Contact us today to learn more about our complete PET bottle washing line and how it can benefit your plastic bottle recycling business.

Main Technical Parameter

| Input Capacity | 500kg/h | 1000kg/h | 1500kg/h | 2000kg/h | 3000kg/h |

|---|---|---|---|---|---|

| Required Space | 42m×10m×6m | 50m×15m×6m | 55m×16m×6m | 60m×18m×6m | 100m×20m×6m |

| Operators | 3-5 people | 6-8 people | 7-9 people | 8-10 people | 10-12 people |

| Installation Power | 150kW | 250kW | 370kW | 450kW | 750kW |

| Water Circulation(T/H) | 2 | 3 | 3 | 4 | 5 |

Post-consumer PET bottles are undoubtedly one of the most important components of the recycling market. Recycled PET can be used in a wide variety of applications and can bring significant financial returns to recycling companies.

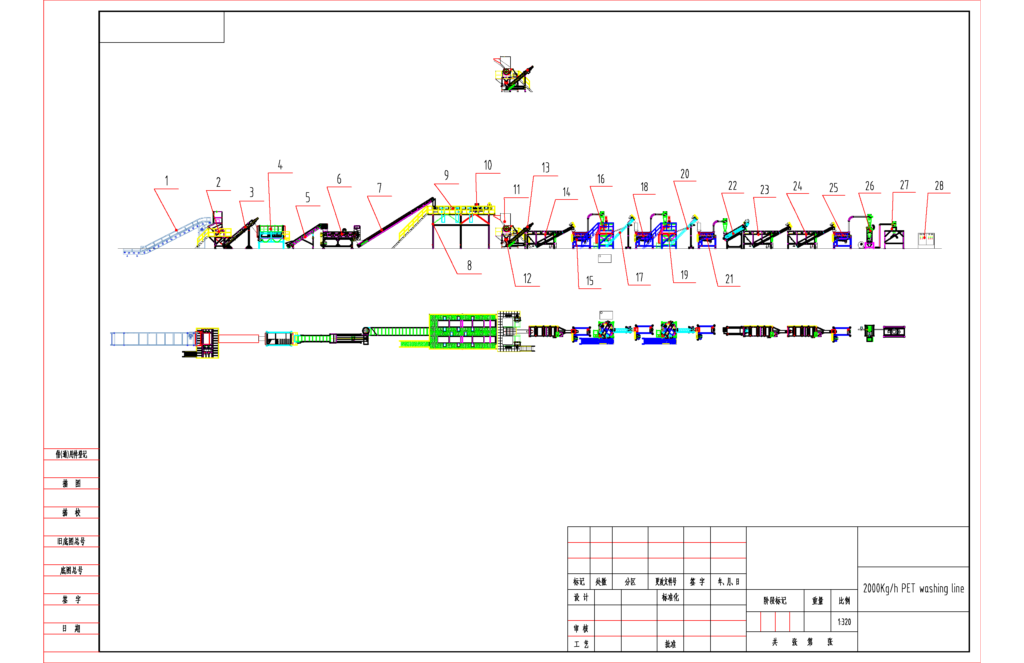

Main system components

Debaler Machine: The first step in our plastic bottle washing line is to break the compacted bales of PET bottles into a free-flowing stream. Once the bales are “busted”, the bottles can move freely onto the next machine.

Trommel: An optional piece of equipment, the trommel is a slowly rotating tunnel lined with small holes that are slightly smaller than the PET bottles. Small pieces of contamination such as glass, metals, rocks/dirt, paper, etc. can fall through the holes while the PET bottles move onto the next machine.

Wet Plastic Granulator: Sometimes referred to as a plastic crusher, our plastic granulator machine cuts the PET bottles into small flakes between 10-15mm in size. With water constantly spraying into the cutting chamber, this wet granulation process pre-treats and partially cleans the material before moving onto the next equipment.

Air Classifier: Air classification is a way to separate lighter materials from heavier ones. The main purpose of using the air classifier is to remove contaminations such as paper, cardboard, and plastic labels away from PET flakes.

Sink/Float Separation Tank: Using water as a medium, materials that float are separated from materials that sink. In the case of plastic bottle recycling, PET plastic will sink while plastic film (bottle labels) and PP/PE plastic (bottle caps) will float. A screw conveyor at the bottom of the sink/float separation tank moves the PET plastic to the next piece of equipment.

Hot Washer System: Hot washed PET flakes are of higher value because this process dissolves glues (used to glue labels onto the bottles) and leftover beverages/foods that are difficult to remove in a cold wash process. Although you can just use water in the hot washer system, adding washing agents can be added for better results.

Friction Washer: An efficient piece of cold water washing equipment, the high-speed friction washer uses friction as a mechanical way to remove any hard-to-remove dirt and debris from the PET flakes.

Dewatering Machine: The first step in the drying process, our centrifugal dewatering machine uses centrifugal force to remove a large portion of water within the PET flakes before moving forward onto our thermal dryers.

Thermal Dryer: PET flakes are vacuumed out of the dewatering machine into the thermal dryer where they travel down a series of stainless steel tubes mixed with hot air. This process removes any remaining moisture by dehydration. An attached cyclone separator mixes the PET flakes with cool air, preparing them for storage in the product silo.

Product Silo: A storage tank for the clean, dry PET flakes.

Pelletizer/Extruder: For the most part, PET flakes are used as is, particularly in manufacturing polyester fibers. However, we do have customers requiring plastic pelletizing machines such as our single-screw extruder pelletizers and twin-screw extruder pelletizers.

| Step | Description |

|---|---|

| De-baling | Separating the PET bottles from baled packages |

| Metal Removal | Separating metal materials using magnets or electromagnets |

| Label Removal | Removing labels from the PET bottles chemically or mechanically |

| Metal Removal | Separating residual metal materials using magnets or electromagnets |

| Bottle Pre-washing | Initial washing of the PET bottles before the washing process |

| Optical Bottle Sorting | Sorting PET bottles by type and color using optical sensors |

| Manual Sorting | Further sorting of PET bottles by hand (by color, type, material, etc.) |

| Crushing | Shredding the PET bottles into small pieces |

| Dust Removal | Removing dust from the shredded PET bottle pieces |

| Flotation Hot washing | Cleaning the PET flakes using hot water in a flotation tank |

| Friction Washing | Removing remaining contaminants from the PET flakes using brushes or other methods |

| Rinsing | Rinsing the cleaned PET flakes to remove any remaining cleaning agents |

| Flushing Washing | High-pressure water rinsing of the PET flakes |

| Drying | Drying the PET flakes using air or a spinning process |

| Dust Removal | Removing any remaining dust from the dried PET flakes |

| Optical Flakes Sorting | Sorting PET flakes by type and color using optical sensors |

| Blending | Blending different colors and types of PET flakes |

| Online Inspection | Inspecting the quality of the PET flakes on the production line |

| Packing | Packaging the PET flakes in bags or other containers |

PS:Equipment configuration and the process will be optimized accordingl to raw materials.

Warranty

All recycling machines come with a 1 year limited warranty.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.