One of the significant benefits of using a Plastic Film Shredding Densifying Line is the versatility of the compressed material. Dense materials can be fed into a repelletizer, used as a raw material for manufacturing new products, recycled, or disposed of. This means that businesses have greater flexibility in how they manage their waste or recyclables.

Another benefit is when transporting recyclables or waste, companies face a significant challenge – the need for economy and efficiency. Loose materials take up a lot of space, which not only increases transportation costs but also damages the bottom line. However, we have come up with an innovative solution to this problem. The Plastic Film Shredding Densifying Recycling Line can compress lighter materials into denser materials that are easier to store or transport.

In conclusion, Plastic Film Shredding Densifying Line offer an innovative and cost-effective solution for businesses that need to transport recyclables or waste like Mixed plastic or PP bags. By compressing lighter materials into denser material, businesses can save money on transportation costs, improve efficiency, and reduce their carbon footprint. Investing in a scrap densification system is a smart decision for any business looking to improve its waste management processes and bottom line.

Using densified plastic film for chemical recycling has become the new trend in recycling PE and PP plastic films in the USA and around the world.

Our Plastic Film Shredding Densifying Recycling Line is your complete solution for turning dirty bales of PP/PE films into densifiedproduct ready for chemical application or processing into plastic granules via pelletizing. We offer standard capacities from 200kg/h up to 1000kg/h and can also manufacture as per your requirements.

we are committed to providing our clients with innovative and efficient solutions to their material transportation needs. Contact us today to learn more about how our Plastic Film Shredding Densifying Line can help your business.

Contents

Advantages of Densifying

Densifying materials can have several advantages, depending on the specific application. Here are some potential benefits of densifying materials:

- Increased Strength and Durability: By reducing the voids and empty spaces in a material, densifying can increase its density and strength. This can make the material more durable and resistant to wear and tear, making it better suited for applications that require high strength and durability.

- Improved Performance: Densifying materials can also improve their performance by enhancing their physical properties, such as thermal conductivity, electrical conductivity, or mechanical properties. For example, densifying metal can improve its thermal conductivity and electrical conductivity, making it a better conductor of heat and electricity.

- Reduced Volume: Densifying materials can also reduce their volume by compressing or condensing them into a tighter form. This can save space, reduce transportation costs, and make the materials easier to handle and store.

- Better Product Quality: Densifying can also improve the quality and consistency of products made from materials. For example, densifying wood can make it less prone to warping or cracking, resulting in higher quality finished products.

- Greater Versatility: By changing the physical and chemical properties of materials, densifying can make them more versatile and suitable for a wider range of applications. For example, densifying plastic can increase its strength and make it more resistant to heat, allowing it to be used in more demanding applications.

Overall, densifying materials can provide a range of benefits, including increased strength and durability, improved performance, reduced volume, better product quality, and greater versatility.

Main Technical Parameter

| Model | RUM-200 | RUM-500 | RUM-1000 |

|---|---|---|---|

| Operation | 2-3 | 2-3 | 2-3 |

| Installation power | 160-200kW | 200-240kW | 400-450kW |

| Knife material | SKD11 | SKD11 | SKD11 |

| Capacity(kg/h) | 200 | 500 | 1000 |

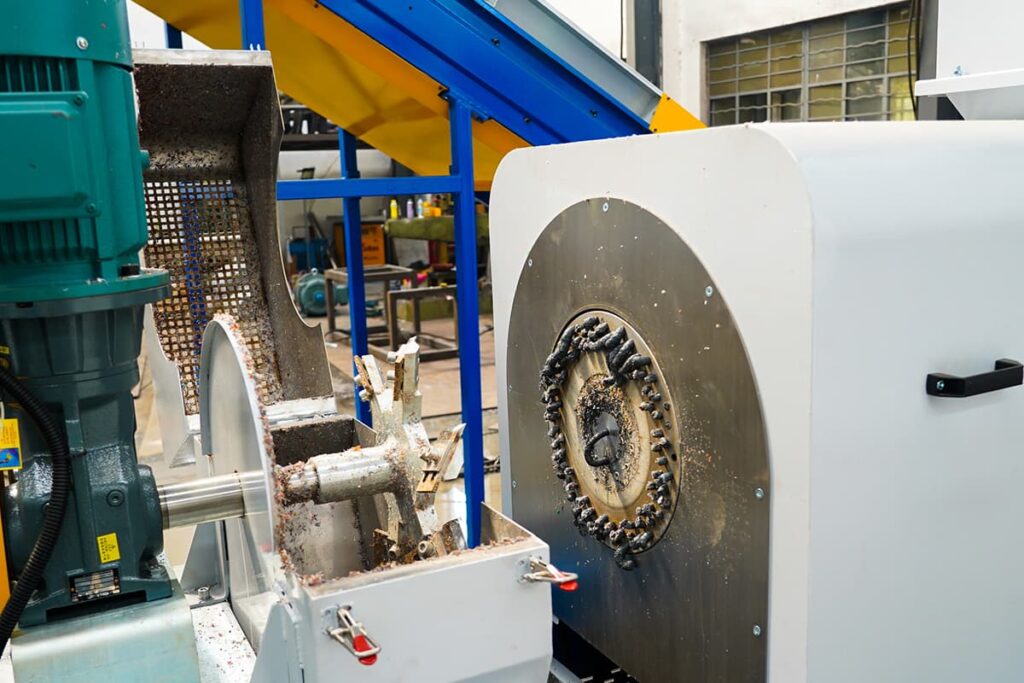

Reliable, multifunctional extrusion dryer can remove 30% to 3% of moisture from plastic (if it is thin film material from the cleaning line), increase surface density of the material by up to 10 times, and compact the processed material.

Working Principle

Key Benefits of using a squeezer dryer for recycling plastics: The plastic squeezer dryer is designed to fit between the washing line and plastic recycling extruder to improve the overall recycling process, which includes:

- Higher output capacity

- Higher efficiency

- Plastic Washing line→Plastic squeezer dryer→Plastic recycling extruder

Our squeezing dryer can effectively dehydrate washed materials, removing water from films, bags, flakes, or fluffy materials. The recycled materials are transformed into flakes or lumps, with their moisture content reduced to just 3% after being squeezed. These denser, less humid lumps or flakes can then be fed directly into a pelletizing extruder, improving the validity, quality, and efficiency of the pellets and the extruder by increasing its capacity.

Plastic Film Shredding Densifying Recycling Line Process:

shred the material into smaller pieces

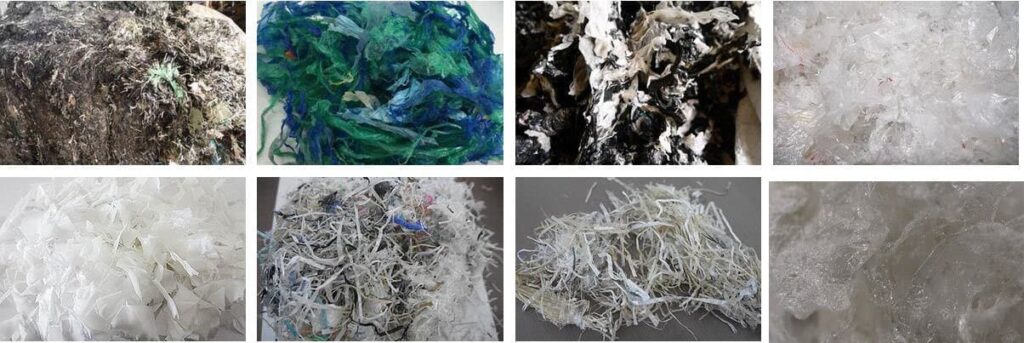

Plastic films, often compacted into bales, are broken down into small pieces using a shredder with a movable hopper.

Wet Granulator

The shredded material is too large for densifying, so the next step is to cut the shreds into small flakes using a wet granulator. Water is sprayed into the cutting chamber to partially wash the material and reduce friction between the knives and plastic.

Sink/Float Tank

The small flakes are then moved along a sink/float tank where they are cleaned, wet, and have contamination removed. Contamination such as mud or stones sink to the bottom of the tank while the plastic film floats on top.

Squeezer

The most important process in the line is the squeezer, which densifies the clean plastic film into irregular pellets using a large screw and heaters. The finished product has a density of approximately 350-410 kg/m3. If the densified material is still too large, an additional granulator can be used to reduce its size further.

By utilizing a shredder, wet granulator, sink/float tank, and squeezer, plastic film waste can be effectively recycled and repurposed. These processes help to reduce waste, conserve resources, and promote sustainability.

Our wash line systems are designed with the application in mind whether post-conusmer, post-industrial or agricultural waste. rumtoo can supply components to upgrade an existing line or provide a complete turnkey solution

Warranty

All recycling machines come with a 1 year limited warranty.

All of our products can be customized according to customer requirements.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.

[contact-form-7 id=”6647″ title=”Contact form 2″]